Product: Hose Handing Solutions

Drive: Electric or Hydraulic

Number of Reels: 1-16

Hose Type: softwall or hardwall

Hose Length: Up to 120m

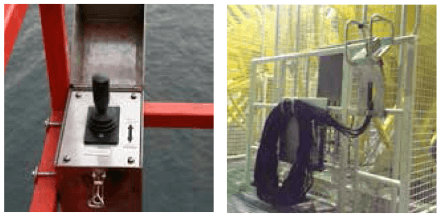

Control: Local control or remote.

Zone (typical): Zone 1, Gas Group 11A/11B, T3

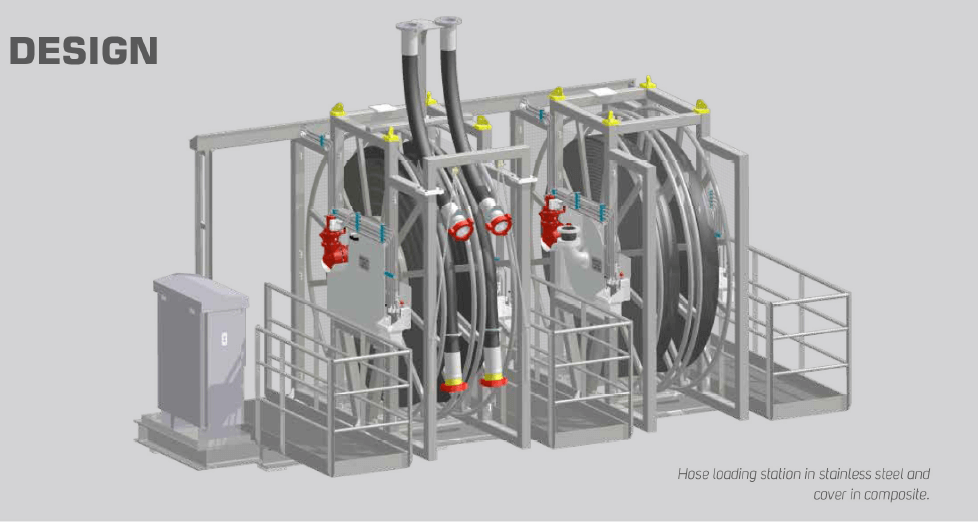

Brayden hose handling winch also named hose reel winch or hose winch which can be delivered in different designs and materials with a range of full control options. Effective loading of fluid and dry bulk materials between fixed and floating production units are necessary to maintain continuous operations. Our hose reel winches are design to provide reliable, safe and efficient fluids transfer in various land and offshore applications.

MATERIAL

Reels are made of in Carbon steel or stainless steel SS316L, Grating and personnel protection can be delivered in composite material if it wanted to reduce weight.

DRIVE SYSTEMS

Our hose handling winch can be manufactured in many type drives of electric, hydraulic and pneumatic driven depending on customers’ requirements and configuration of reels.

Standard reels are fabricated with hydraulic drive. The stations can be connected to ring line or existing hydraulic power supply onboard the rig/vessel or they can be delivered with dedicated HPU’s either placed on the skid or somewhere nearby.

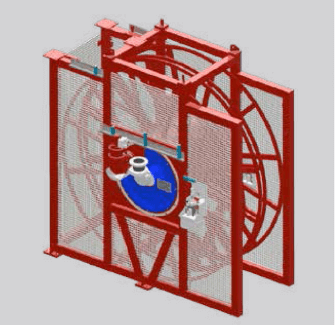

SWIVEL SOLUTIONS

All reels for fluid material are delivered with swivel on the reel. Reels for dry bulk materials are designed without swivel on the reel to avoid pressure loss. Normally swivels can be made of carbon or stainless steel.

REEL CONTROL

Reels are designed in a range of control options depending on customer’s requirements. Large bulk loading stations are typically delivered with radio control or remote control with cable. Single or double reels are typically manufactured with local control.

SAFETY AND PROTECTION

Brayden bulk loading station are delivered with various options for personnel protection in steel or composite according to project specific requirements.

Different safety standards are used depending on project, but typical standards used in design phase to ensure safety for personnel are: ● Cement ● Bentonite/Barite etc. ● Oil based Mud ● Water based Mud ● Brine Depending on customer’s requirements and prevailing standards for the project we offer three different types of safety guard: ● Covered reels ● Safety guard mounted on the outside of the reels ● Safety guard mounted on frame for reels

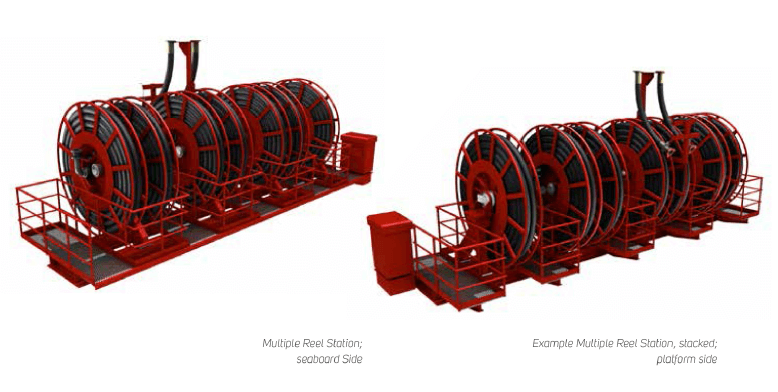

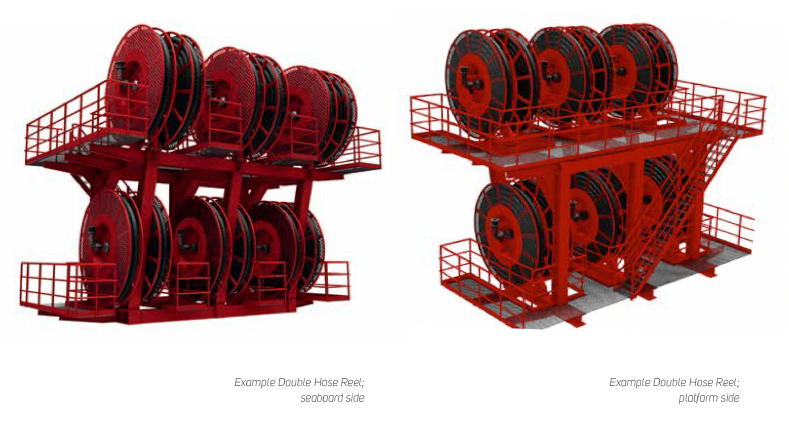

MULTIPLE REEL STATION

MULTIPLE STACKED REEL STATIONS

Increased safety for equipment.

Add safety for personal in hostile offshore environment.

Less time needed for operation.

Reduced need for operation personnel-one man operated.

Environment protection and protection from spillage.

No more long hours of exposure to sunlight resulting in longevity of hose life.

Increased lifespan of the hoses due to less water and tear.

Less chance for hose fatigue failure.

Space saving onboard the vessel/rig.

Easy access for maintenance and service.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours