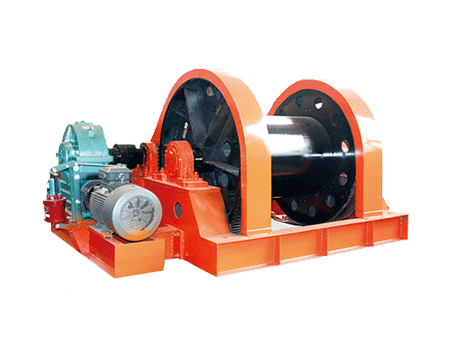

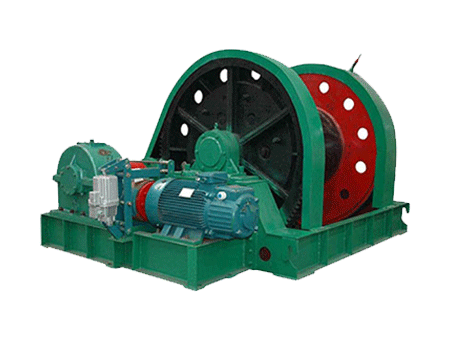

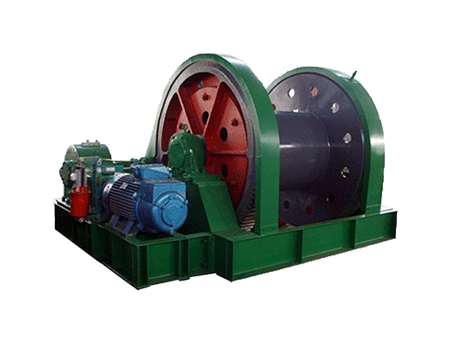

Product: Shaft Sinking Winch

Model: JZ

Lifting Capacity (Ton): 5-16

Drum Capacity (m): 400-1000

Lifting Speed (m/min): 6

Max. Static Tension (KN): 50-160

JZ Series electric shaft sinking winch is mainly used for hoisting tray, water pump, water pipe, grouting pipe, air duct and other driving equipment and tensioning rope during shaft driving in coal mine, metal mine and non-metal mine during the shaft construction period. The winch is mainly used to replace the tail rope connected between two cages of the hoist. And for the best flat rope, can also be used for a vertical shaft winch, and its performance is the same as the vertical shaft. JZ series sinking winch has the advantages of strong lifting capacity, large rope capacity and smooth operation.

Electric shaft sinking winch mainly used as the tension and stability rope of the excavating equipment, such as suspension tray water pump air pipe, compressed air pipe grouting pipe, etc., in the shaft driving engineering of coal mine, metal mine and non-metal mine, and can also be used for other heavy lifting underground and on the ground. The sinking winch has the advantages of strong lifting capacity, large rope capacity and smooth operation.

The drum of shaft sinking winch is designed according to the latest elasticity theory, and high-strength low-alloy steel Q345A is selected as the shell material. There are two types of integral welding and partial bolt connection. For the convenience of maintenance or replacement during transportation, it can also be cut into Fraction.

| Model | Max. static tension of steel wire rope | Rope capacity | Reel specification | diameter of wire rope | Number of winding layers | First layer of wire rope speed | Electric motor | Dimension | Weight | |||||||||

| dia. | width | height of center | fast | slow | model | power | rotational Speed | voltage | length | width | height | |||||||

| KN | m | mm | mm | mm | m/s | m/s | KW | rpm | V | mm | mm | mm | kg | |||||

| JZ10/600 | 100 | 600 | 800 | 1050 | 900 | 32 | 8 | 0.084 | 0.042 | YRT250M2-8 | 22 | 730 | 380 | 2483 | 2962 | 1728 | 7280 | |

| JZ10/800 | 100 | 800 | 800 | 820 | 900 | 32 | 8 | 0.084 | 0.042 | YRT250M2-8 | 22 | 730 | 380 | 2883 | 2962 | 1728 | 7480 | |

| JZ16/800 | 160 | 800 | 1000 | 1400 | 1050 | 40 | 7 | 0.078 | 0.039 | YRT250M2-8 | 30 | 730 | 380 | 3600 | 3280 | 2300 | 1150 | |

| JZ16/1000 | 160 | 1000 | 1000 | 1400 | 1050 | 40 | 7 | 0.078 | 0.039 | YRT250M2-8 | 30 | 730 | 380 | 3600 | 3280 | 2300 | 11500 | |

| JZ16/1320 | 160 | 1320 | 1000 | 1400 | 1200 | 40 | 10 | 0.078 | 0.039 | YRT250M2-8 | 30 | 730 | 380 | 3600 | 3280 | 2300 | 12100 | |

| 2JZ16/1000 | 160 | 1320 | 1000 | 1400 | 1050 | 40 | 8 | 0.078 | 0.039 | YRT280S-8 | 55 | 723 | 380 | 5726 | 3806 | 2988 | 18000 | |

| 2JZ16/1320 | 160 | 1320 | 1000 | 1400 | 1050 | 40 | 10 | 0.078 | 0.039 | YRT280S-8 | 55 | 723 | 380 | 5726 | 3806 | 2988 | 18800 | |

| JZ25/1000 | 250 | 1000 | 1050 | 1210 | 1325 | 52 | 10 | 0.081 | 0.04 | YRT280S-8 | 45 | 732 | 380 | 3890 | 3935 | 2620 | 14680 | |

| JZ25/1320 | 250 | 1320 | 1050 | 1500 | 1326 | 52 | 10 | 0.081 | 0.04 | YRT280S-8 | 45 | 732 | 380 | 4180 | 3935 | 2620 | 14680 | |

| JZ40/1000 | 400 | 1000 | 1250 | 1480 | 1500 | 60 | 9 | 0.087 | 0.043 | YRT355S-8 | 90 | 730 | 380 | 4725 | 4593 | 3300 | 35000 | |

| JZ40/1800 | 400 | 1800 | 1250 | 2060 | 1500 | 60 | 10 | 0.087 | 0.043 | YRT355S-8 | 90 | 730 | 380 | 4305 | 45936 | 3300 | 35000 | |

All equipped with explosion-proof motor and electrical control units.

Compact structure, good rigidity, high efficiency, convenient installation and movement.

Light dead weight, easy handling, stable operation, easy maintenance and simple operation.

Low speed and heavy load non-continuous work.

Performance of flameproof, safe and reliable, long service life.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours