Product: Shark Jaw

Type: Customized

Drum Capacity: Customized

Drive: hydraulic with HPU

Application: Drilling Platform, Tugboat, Towing Vessel

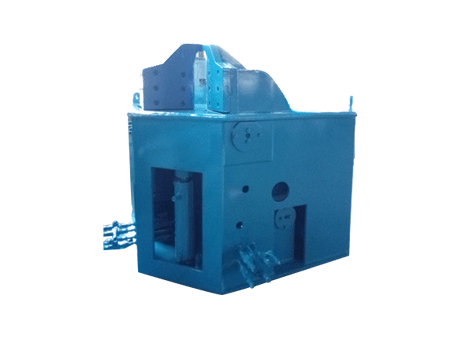

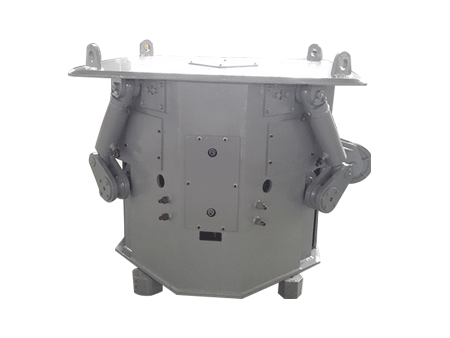

Shark Jaw is a marine safety device. The main function is to hold the cable or steel rope tightly to prevent the sliding of the cable, steel rope and anchor chain. Shark jaw device consists of shark jaw installed on the stern deck, bollard, tail roller, hydraulic pump station and electric control system. The shark pincer device designed by Brayden Machinery for the three-purpose tugboat is responsible for the three tasks of towing, anchor lifting and supply. In order to safely, quickly and effectively carry out the anchoring operation for the drilling platform, the newly designed three-purpose tugboat is equipped with a shark tong device without exception. At present, shark pincers are widely used in various boats.

Shark pincers are installed at the stern of the ship, and are mostly a combination of shark tongs and tow pins. The shark tongs can be used to clamp the anchor chain or wire rope for temporary fixation, and the tow pin can be used to limit the swing of the anchor chain or wire rope for safety protection. It can be applied to the needs of engineering ships such as three-purpose work ships and platform supply ships, and can realize various offshore engineering operations with towing machines. The product is designed based on the concept of standardization, modularization and serialization, and can be tailored to meet the needs of different users.

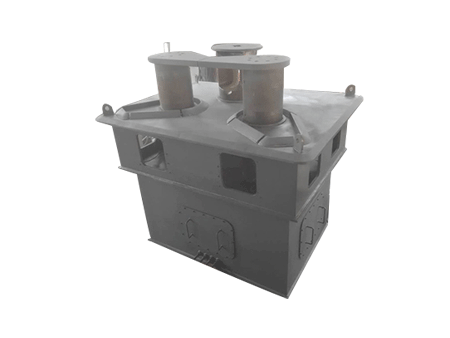

Shark jaw is also called hydraulic chain stopper or hydraulic cable clamp. The English name is shark jaw. There are two types, one is fork type: FORK Jaw. The other link type is triplex shark jaw. When the towing machine needs to tow, raise the shark jaw and tow pin, remove the cover of the shark jaw, and open the jaw. Connect the towed object with a wire rope, and the end of the wire rope is pulled to the tugboat, passed through the middle of the two fairleads of the tow pin, and then passed through the jaws of the shark tongs. Close the jaws and clamp the end of the wire rope (usually there is a connecting collar).

At this time, the wire rope of the towing machine can be connected with the wire rope of the towed object. Since the wire rope of the towed object has been clamped with shark pliers, there will be no danger when connecting the wire rope due to the influence of wind and waves. After connecting the wire rope, use the towing machine to tighten the wire rope, open the jaws of the shark tongs, install the cover of the shark tongs, and lower the shark tongs. Properly releasing a section of wire rope, the towing work can be carried out. During the towing process, the wire rope is always in the middle of the two fairleads of the towing pin. When the ship is turning, the wire rope will not swing left and right, so as to avoid damage to the ship's side and wire rope.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours