Product: Mine Hoist

Model: JK/JKB

Lifting Capacity (Ton): 1-3.5

Hoisting Height (m): 300-2000

Lifting Speed (m/s): 2.5-6.8

Max. Static Tension (KN): 60-170

Anti-explosion: With or without

Mine hoist refers to the main transportation equipment connecting the underground and the ground in mining engineering site. Mine winder is a lifting machine which is installed on the ground and drives the lifting vessel along the shaft or slope with the help of wire rope. Brayden offer JK series single rope winding type mine lifting hoist is mainly used for lifting coal, materials, lifting personnel, descending materials and equipment in vertical shafts or inclined shafts of coal mines, metal mines and non-metal mines. Also it can be used for pulling and transferring other objects.

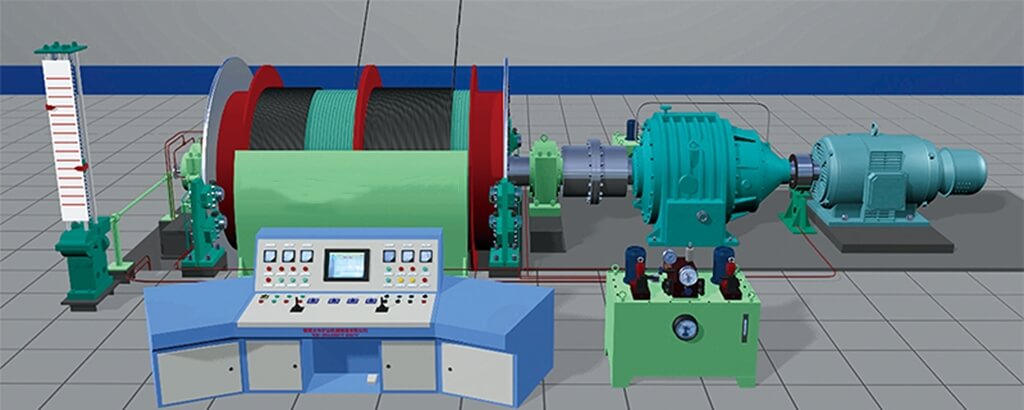

3D Overall Design of Mine Hoist

Mine winder consists of power system, transmission system, working system, braking system, control and operation system, indicating protection system, etc. and its ancillary parts. It uses the motor power source, through the reducer and the main shaft device to form the efficient transmission system and working system of the product. The hydraulic station and brake device constitute the product's reliable braking system; the operating console and electrical control equipment constitute the product's complete control and manipulation system; the depth indicator and encoder device constitute the product's complete indication and protection system.

| Model | Drum | Max. static tension of wire rope | Wire rope maximum tension difference | Max. lifting height | Wire Rope | Reduction ratio | Average lifting speed | Electric motors | Dimension | Weight | |||||||||||

| number | dia. | width | Center distance of two reels | manned | loaded | manned | loaded | One-layer | Two-layer | Triple Wrap | Max. diameter | Total breaking force | Rotation speed | Max. power | length×width×Height | ||||||

| mm | KN | m | mm | KN | m/s | r/min | KW | mm | kg | ||||||||||||

| 2JK-3.5×1.7 | 2 | 3500 | 1700 | 1790 | 136 | 170 | 115 | 424 | 853 | 1283 | 43 | 1230 | 30 | 4.6 | 750 | 630 | 10360×5020×4060 | 87031.7 | |||

| 2JK-3.5×1.7P | 2 | 3500 | 1700 | 1790 | 136 | 170 | 115 | 424 | 853 | 1283 | 43 | 1230 | 30 | 4.6 | 740 | 630 | 10360×5020×4060 | 87031.7 | |||

| JK-3.5×2.5 | 1 | 3500 | 2500 | / | 136 | 170 | 136 | 170 | 624 | 1255 | 1895 | 43 | 1230 | 30 | 4.5 | 742 | 900 | 9950×5020×4060 | 76017.4 | ||

| JK-3.5×2.5P | 1 | 3500 | 2500 | / | 136 | 170 | 136 | 170 | 624 | 1255 | 1895 | 43 | 1230 | 30 | 4.5 | 740 | 900 | 9950×5020×4060 | 76017.4 | ||

| 2JK-3×1.5 | 2 | 3000 | 1500 | 1590 | 100 | 135 | 90 | 371 | 747 | 1126 | 36 | 900 | 30 | 3.9 | 739 | 400 | 12560×4380×2730 | 68687.7 | |||

| 2JK-3×1.5P | 2 | 3000 | 1500 | 1590 | 100 | 135 | 90 | 371 | 747 | 1126 | 36 | 900 | 30 | 3.9 | 741 | 400 | 12560×4380×2730 | 68687.7 | |||

| JK-3×2.2 | 1 | 3000 | 2200 | / | 100 | 135 | 100 | 135 | 545 | 1096 | 1652 | 36 | 900 | 30 | 3.9 | 739 | 560 | 9730×4380×2730 | 53896 | ||

| JK-3×2.2P | 1 | 3000 | 2200 | / | 100 | 135 | 100 | 135 | 545 | 1096 | 1652 | 36 | 900 | 30 | 3.9 | 741 | 560 | 9730×4380×2730 | 53896 | ||

| 2JK-2.5×1.5 | 2 | 2500 | 1500 | 1590 | 69 | 83 | 65 | 369 | 742 | 1119 | 30 | 621 | 31.5 | 4.0 | 974 | 245 | 8520×3610×2600 | 44254 | |||

| 2JK-2.5×1.5P | 2 | 2500 | 1500 | 1590 | 69 | 83 | 65 | 369 | 742 | 1119 | 30 | 621 | 31.5 | 4.0 | 974 | 260 | 8520×3610×2600 | 44354 | |||

| 2JK-2.5×1.2P | 2 | 2500 | 1200 | 1290 | 69 | 83 | 55 | 294 | 591 | 892 | 30 | 621 | 31.5 | 3.1 | 740 | 250 | 7374×3610×2600 | 39989 | |||

| JK-2.5×2.3 | 1 | 2500 | 2300 | / | 69 | 83 | 69 | 83 | 564 | 1134 | 1711 | 30 | 621 | 31.5 | 4 | 975 | 320 | 7540×3610×2600 | 38580 | ||

| JK-2.5×2.3P | 1 | 2500 | 2300 | / | 69 | 83 | 69 | 83 | 564 | 1134 | 1711 | 30 | 621 | 31.5 | 4 | 935 | 325 | 7540×3610×2600 | 38580 | ||

| JK-2.5×2P | 1 | 2500 | 2000 | / | 69 | 83 | 69 | 83 | 490 | 986 | 1488 | 30 | 621 | 31.5 | 3.1 | 740 | 315 | 6702×3610×2600 | 33912 | ||

| 2JK-2×1.25 | 2 | 2000 | 1250 | 1340 | 44 | 61 | 40 | 296 | 595 | 898 | 24 | 396.5 | 31.5 | 3.2 | 973 | 132 | 7960×3234×2600 | 27798.5 | |||

| 2JK-2×1.25P | 2 | 2000 | 1250 | 1340 | 44 | 61 | 40 | 296 | 595 | 898 | 24 | 396.5 | 31.5 | 3.2 | 973 | 132 | 7960×3234×2600 | 27798.5 | |||

| 2JK-2×1P | 2 | 2000 | 1000 | 1090 | 44 | 61 | 40 | 236 | 475 | 717 | 24 | 396.5 | 31.5 | 2.5 | 740 | 160 | 6740×3234×2600 | 25937 | |||

| JK-2×1.8 | 1 | 2000 | 1800 | / | 44 | 61 | 44 | 61 | 426 | 857 | 1294 | 24 | 396.5 | 31.5 | 3.2 | 975 | 180 | 7450×3234×2600 | 24628.8 | ||

| JK-2×1.8P | 1 | 2000 | 1800 | / | 44 | 61 | 44 | 61 | 426 | 857 | 1294 | 24 | 396.5 | 31.5 | 3.2 | 975 | 185 | 7450×3234×2600 | 24628.8 | ||

| JK-2×1.5P | 1 | 2000 | 1500 | / | 44 | 61 | 44 | 61 | 355 | 714 | 1078 | 24 | 396.5 | 31.5 | 2.5 | 740 | 220 | 6160×3234×2600 | 23229 | ||

| JKB-2.5×2.3P | 1 | 2500 | 2300 | / | 83 | / | 429 | 867 | 1312 | 40 | 747 | 31.5 | 3 | 740 | 320 | 7000×3610×2600 | 39620.6 | ||||

| JKB-2.5×2P | 1 | 2500 | 2000 | / | 83 | / | 373 | 755 | 1143 | 40 | 747 | 31.5 | 3 | 740 | 315 | 6700×3610×2600 | 36998.8 | ||||

| JKB-2×1.8P | 1 | 2000 | 1800 | / | 83 | / | 332 | 670 | 1013 | 32 | 558 | 31.5 | 2.5 | 735 | 200 | 6410×3234×2600 | 25560 | ||||

| JKB-2×1.5P | 1 | 2000 | 1500 | / | 83 | / | 277 | 557 | 842 | 32 | 558 | 31.5 | 2.5 | 740 | 200 | 6160×3234×2600 | 24782 | ||||

The cylinder rear disc brake is adopted, and the electric-hydraulic joint control is adopted.

Adopt (hydraulic axial) or radial gear block type rope adjustment clutch, which can adjust the rope accurately and quickly.

The electric pull can use PLC programming electric control or PLC control frequency conversion electric control.

Drum is welded by low-carbon alloy steel plates, high adaptability and anti-fatigue strength.

The brake disc is made of 160Mn plates, anti-deformation, high wear resistance.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours